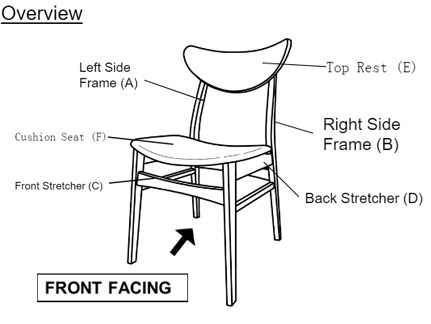

In the home furnishing market, affordable wooden dining chairs have always been one of the wooden furniture favored by consumers. Whether it is your own dining room, living room, or restaurants and hotels of various grades, simple and elegant wooden dining chairs can be seen everywhere. Wooden dining chairs also account for a considerable proportion of furniture sales. Therefore, with the vigorous development of wooden dining chair manufacturers, it is very important to develop products such as coatings and colorants suitable for wooden dining chair coatings in the furniture market.

At present, solvent-based wood coatings commonly used for wooden dining chairs include polyurethane (PU) paint, nitro (NC) paint, alkyd paint, unsaturated polyester (PE) paint, ultraviolet curing (UV) paint, acid curing ( AC) paint, etc. Medium-scale dining chair manufacturers mostly adopt assembly line production, which is characterized by high production efficiency, stable product quality, and short delivery time intervals after receiving orders from furniture factories. This determines that the coating for wooden dining chairs needs to have the following characteristics: easy to use, fast drying, fast odor disappearing, etc.

Both PU paint and PE paint are reaction-curing systems, and there is a problem of service life in the process of use; UV paint is also a multi-component system, which requires special ultraviolet light source irradiation to react and form a film, and wood products with complex shapes are not suitable for use; AC paint Slow drying, unsatisfactory paint film performance; alkyd paint is slow drying, etc. None of the above types of coatings are suitable for coating wooden dining chairs. At present, NC paint is the most commonly used for wooden dining chairs. NC paint is a one-component physical drying film-forming coating, and it has good resistance to daily chemicals.

However, with the country's emphasis on environmental protection and the improvement of customer requirements, furniture factories have higher and higher requirements for environmental protection of coatings. Because NC paint produces a large amount of VOC (volatile organic compounds) during use, it causes great pollution to the environment, and also causes a large amount of energy consumption and waste, and is easy to burn and explode. The application of water-based wood coatings has been rapidly developed. develop. Compared with solvent-based coatings, water-based wood coatings have the following advantages: the solvent used is mainly water, which greatly eliminates the risk of fire during construction; it only contains a small amount or does not contain low-toxic alcohol ethers Organic solvents improve the construction environment of the factory and reduce air pollution during construction; most of them are single-component types, and the construction method is simple; they can be directly coated on wet surfaces containing water or in humid environments. Good applicability and strong coating adhesion; coating tools can be cleaned directly with water, which greatly reduces the consumption of cleaning solvents and plays a role in energy saving and consumption reduction.

With the increasing popularity of ceramic frame design, artisans and designers have been relentlessly exploring innovative ways to enhance this elegant art form. Ceramic frames not only serve as funct...

New home decoration is completed, due to the wall, nail material differences, there are often walls too hard, nails bent, but still not nailed into the wall; wall putty and stucco layer is too soft, n...

When it comes to decorating a child's room, every parent wants to create a space that is not only visually appealing but also reflects their child's personality and interests. One way to add a...

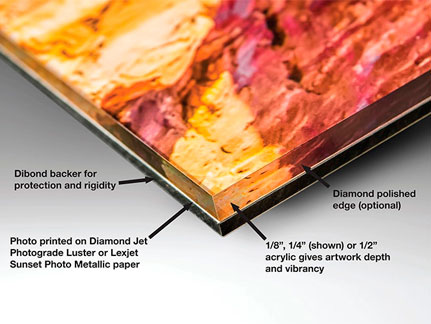

Acrylic photo frame is a photo frame made of acrylic material. For acrylic, we don't know what kind of material it is, plexiglass, this kind of photo frame is very popular in recent years. What ty...

A good dining table can bring a more pleasant feeling to people's dining. In order to bring people a more comfortable dining experience, a solid wood dining table is recommended. Speaking of a sol...

The material used for the wooden dining table is not reprocessed, it is very natural, and there is no composition of wood-based panels. After we buy a solid wood dining table, we need to maintain the ...

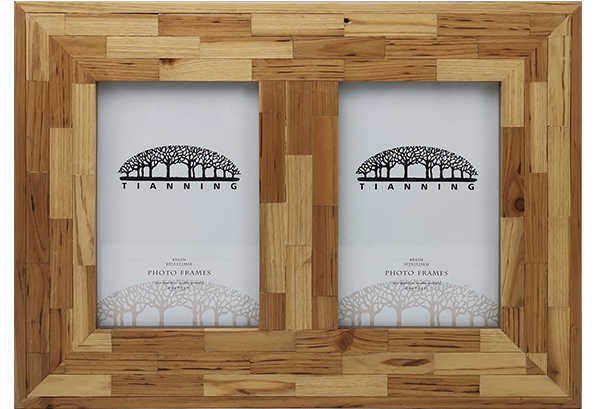

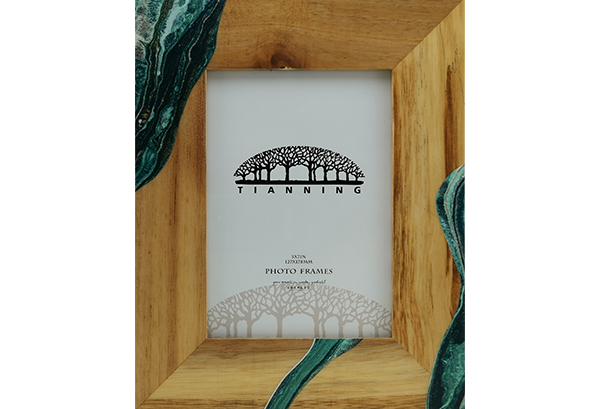

1. Material of solid wood photo frameNowadays, most of the real photo frames are made of pine, birch, and tussah. After processing, such as excavation, drying, and anti-moth, the pine has clear textur...

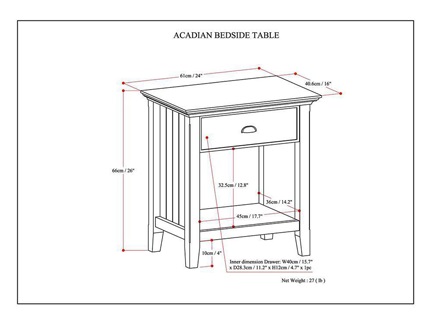

The bed bedside table is mainly placed on both sides of the bedside. It belongs to a small vertical cabinet that can accommodate some sundries. Because the furnishings of the bed bedside table also pl...

Fashion jewelry box to use, besides can prevent loss of jewelry, also can protect the jewelry, therefore the existence of the box can effectively slow down the oxidation of jewelry, increase the servi...

Acrylic modern photo frame is one of the more popular photo frames on the market now, which has great advantages over glass and plastic photo frames. There are many styles of acrylic photo frames, and...

Solid wood photo frames are also called wooden photo frames and wooden photo frames, that is, photo frames made of wood as raw materials. Common fir, pine, oak, paulownia, oak and so on. The most comm...

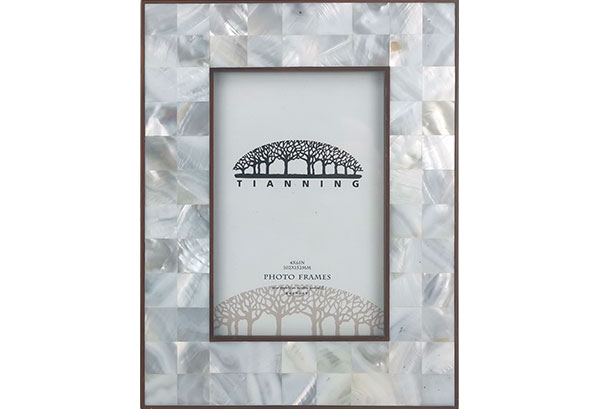

It's everyone's nature to love beauty, especially girls who love beauty more, they often take many photos and place them so that they can see them at any time. When it comes to photos, of cour...

Decorating our homes is a reflection of our personal style and taste. Every element plays a crucial role in creating a visually appealing ambiance, and picture frames are no exception. Silver plated p...

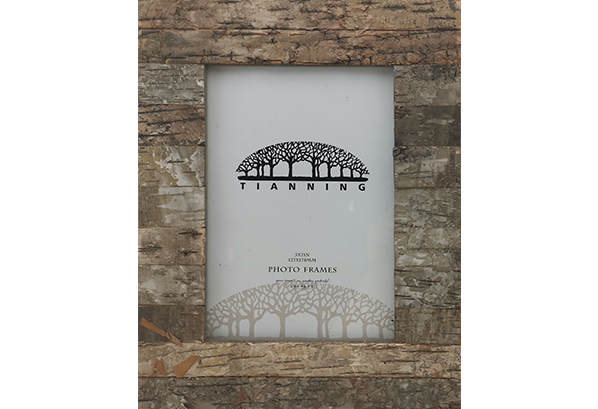

Tree bark picture frames are a unique and beautiful way to display cherished memories captured in photographs. The rustic and organic appearance of these frames adds a touch of nature to any interior ...

Photo frames are born for packaging photos, and are also a very popular way of home decoration in recent years. Photo frames are used to frame memories and make people taste happiness and sweetness. D...

In order to make the solid wooden table stable and not easily damaged, besides the most important drying treatment, different coating methods are also used to protect the wood and extend its service l...

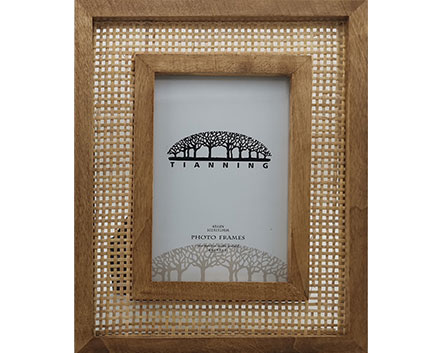

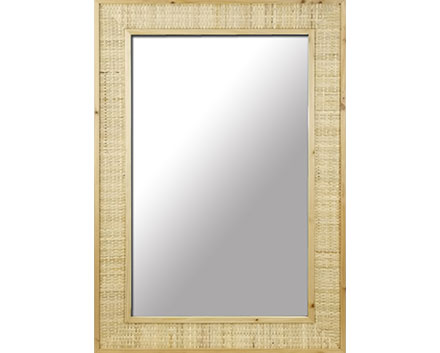

Cane photo frames are a charming and elegant way to display your favorite memories. They add a touch of natural beauty to any space, whether it's a living room, bedroom, or office. However, just l...

Wedding photos are a lifetime of memories and in order to preserve these memories, they are usually framed and placed in a corner of the home. Therefore, it is important to choose a good frame and it ...

The more you pay attention to the taste when choosing dining chairs, dining chairs made of different materials will have different decorative effects in the decoration. More people begin to like the b...

Cane photo frames offer a unique and elegant way to display cherished memories. Whether you want to add a touch of rustic charm to your home decor or give a thoughtful gift to a loved one, choosing th...

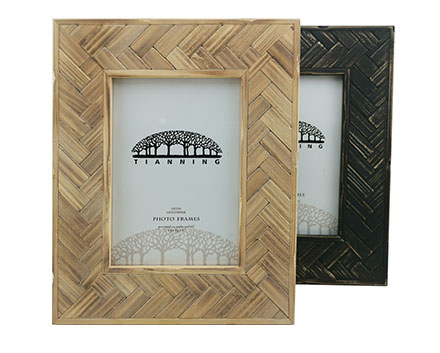

Solid wood photo frames have always been loved by people, especially some antique lovers, retro style lovers, and small fresh dress lovers. The reason why wooden frames are popular is that the wood is...

Among many photo frames, solid wood photo frames have always been loved by people. Every household will prepare two solid wood photo frames and put their photos in them for better preservation and app...

I. The influence of arts and crafts on natural wood jewellery boxesThe classification of arts and crafts is relatively simple, with the main categories being display crafts and everyday crafts. The ar...

Decorative picture frames include solid wood picture frames and PS (polystyrene) picture frames, both of which have their own characteristics. When choosing a picture frame to decorate your walls, it&...

Art has the power to inspire, evoke emotions, and create a lasting impression. It is an expression of the human imagination, skillfully crafted to tell stories and convey messages. Whether it be a pai...

We, Ren and Tim with frames, have just finished the journey at Canton Fair 2021 at this Tuesday. Two seasons every year, it's a good opportunity to check out the renovation of made in china&...

Wooden jewelry box packaging has become an important part of jewelry, it is related to the production, circulation, consumption of each link. Jewelry is more direct with consumer contact supplies.1. T...

Home decor trends are ever-evolving, and one trend that has captured the hearts of design enthusiasts is the rustic chic aesthetic. In this blog, we explore the charm and versatility of cane photo fra...

Compared with furniture made of other materials, solid wood furniture is more secure for consumers to use, especially in terms of environmental protection, solid wood materials are safer, so consumers...

We all know that the solid wooden dining chair is a table for dining made of solid wood as the main material. Generally speaking, furniture made of solid wood is rarely mixed with other materials, bec...

The wooden jewelry box requires attention to detail in designCurrently, many jewelry boxes made of wood on the market are mainly marketed using packaging box shapes and colors. As the external image o...

Nowadays, there are many kinds of jewelry box materials on the market, such as paper, PU, leather, wood, etc., each with its own advantages. Today, let's take a look at the advantages of wooden je...

We all know that the photo frame is similar to a rectangle. Generally speaking, it is hollow inside, and then just put some photos we need in the blank space. It is mainly used for the identification ...

The restaurant is a space for people to enjoy food in the family. The warm and comfortable dining environment can not only enhance the appetite but also make people relax and feel the romance and warm...

Nowadays, people pay great attention to environmental protection. At home, furniture made of inferior materials will release harmful substances such as formaldehyde and benzene. Therefore, purchasing ...

Beautiful jewelry is the favorite of women, but when you take out these jewelry, have you noticed their jewelry box? Thinking about it carefully, the jewelry boxes we see on weekdays seem to be simila...

On a certain day in a certain year and month, you will miss the childhood memories of roasted sweet potatoes and corn by the fireplace, the delicious meals cooked by your mother after school, and the ...

After completing the first step of wall decoration, the next step is to focus on details and choose suitable decoration methods to further decorate the wall and bring it to life. The following decorat...

A warm home can only be built by the owner's careful layout. In addition to the daily furniture and home appliances, some small details are also very important. For example, using a photo frame to...

Today, there are a variety of materials for jewelry boxes on the market, such as paper, PU, leather and wood, each with their own advantages. Today we will learn about the advantages of wooden jewelry...